The Crucial Role of Yeast Rehydration

The Key to Unlocking the Full Potential of Active Dry Yeast

When we think about the magic behind a great bottle of wine, our minds often drift to picturesque vineyards, plump grapes, and perhaps a seasoned vintner swirling a glass under the Tuscan sun. But one of the most crucial elements in this enchanting process lies within the realm of microbiology: yeast. More specifically, active dry yeast (ADY), a powerhouse in the winemaking industry, holds a secret key to crafting exceptional wines.

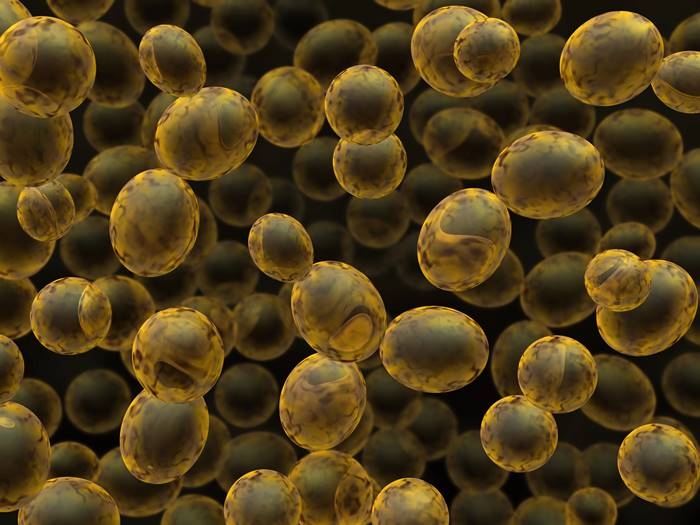

Active dry yeast might not have the glamorous image of sun-ripened grapes, but it's indispensable in modern winemaking. These tiny, dehydrated organisms are champions in resilience and practicality. Unlike their fresh or liquid counterparts, ADY contains only 5-8% water, making it cheaper and easier to transport. With the water weight reduced, ADY is compact and doesn't require refrigeration to maintain its vitality. This means it can travel at room temperature and stay viable for over three years.

The first critical step in using ADY is rehydration. This process is akin to waking up these dormant yeast cells and preparing them for the hard work ahead. Winemakers rehydrate ADY in water heated to 35-40°C. This brief but vital period helps restore the yeast's membrane functionality and metabolism. Once rehydrated, these lively yeast cells are introduced to the grape must, the sweet, unfermented juice that will soon transform into wine.

When ADY meets the grape must, it's thrown into a challenging environment. The must is high in sugar and low in pH, a stress cocktail for yeast cells. Additionally, as fermentation progresses, nutrients dwindle, and ethanol levels rise, further straining the yeast. Ensuring that the yeast remains healthy through this demanding process is crucial. That's why proper rehydration is more than a mere step; it's a linchpin for a successful fermentation. Directly adding ADY to the must without rehydration can jeopardize the fermentation process, potentially resulting in a less than stellar wine.

Feeding the Yeast

Nutrients are the lifeblood for yeast. They support growth, protein synthesis, and overall metabolism, all of which impact fermentation speed and the production of aromatic compounds. Before fermentation kicks off, rehydrating the yeast in an optimal nutrient-rich environment is essential. This ensures that the yeast not only survives but thrives, which in turn helps create a robust and aromatic wine.

Inactive yeast preparations are often added to the rehydration medium. These preparations are rich in essential compounds like amino acids, sterols, vitamins, and minerals. These elements enhance the yeast's viability and vitality by supporting membrane structure and function. This boosts the yeast's ability to propagate and withstand the rigors of fermentation, ultimately contributing to a well-rounded wine profile.

The Magic of Magnesium

Magnesium (Mg2+) plays a critical role in yeast metabolism. It's a cofactor for over 300 enzymes, including those involved in glycolysis, alcohol production, and fatty acid synthesis. In a nutrient-limited environment, magnesium deficiency can halt yeast growth and even cause cell death. Thus, ensuring an adequate supply of magnesium during rehydration and fermentation is vital for maintaining a healthy yeast population.

Active dry yeast may not be the star of the winemaking show, but it's certainly a key player behind the scenes. From its ease of transport and long shelf life to its critical role in fermentation, ADY is a staple in the winemaker's toolkit. The rehydration process, often overlooked, is pivotal in setting the stage for a successful fermentation and, ultimately, a delightful bottle of wine. So, next time you sip your favorite vintage, remember the tiny, tireless yeast cells that helped make it all possible.

Founded in 2007, Vinetur® is a registered trademark of VGSC S.L. with a long history in the wine industry.

VGSC, S.L. with VAT number B70255591 is a spanish company legally registered in the Commercial Register of the city of Santiago de Compostela, with registration number: Bulletin 181, Reference 356049 in Volume 13, Page 107, Section 6, Sheet 45028, Entry 2.

Email: [email protected]

Headquarters and offices located in Vilagarcia de Arousa, Spain.