The meticulous journey of white wine: from vine to glass

The process of white wine production

The production of white wine, an elegant and beloved beverage, involves a meticulous and complex process. This article delves into the seven fundamental steps of transforming grape must into the refined white wines that grace tables worldwide.

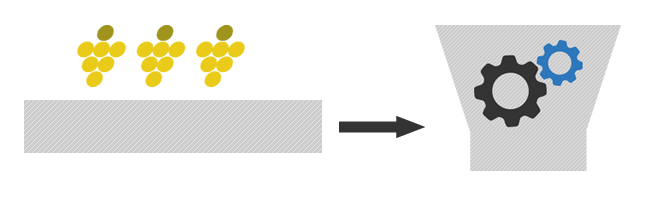

Destemming and Crushing

After the grapes are harvested, a critical first step is the separation of the grapes from the stems, a process known as destemming. This can be done using specialized machinery and is often optional. The crushing process follows, where the grapes are gently pressed to avoid breaking the seeds and stems. The resulting mixture, known as the pomace, is used in the production of various spirits.

Maceration

Maceration is the process where the grape skins are allowed to remain in contact with the must for a variable number of hours. This step is essential for transferring the aromatic substances from the skins to the must, especially in the production of high-quality white wines. However, it is an expensive process and is often reserved for premium wine production.

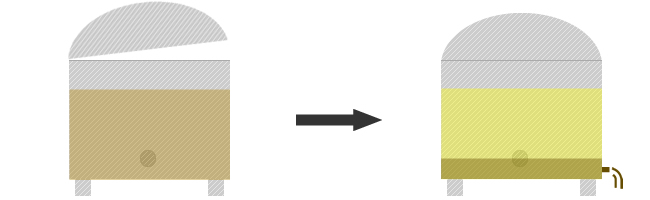

Draining

This optional process aims to obtain a higher quality must. It is performed by simply letting gravity do its work, allowing the liquid to separate from the solid parts.

Decanting

Following maceration and draining, the wine is separated from any remaining solids and particles, also known as lees. This is achieved by allowing the wine to rest so that these particles settle at the bottom. Decanting can sometimes occur simultaneously with maceration, preventing fermentation and purifying the wine by maintaining a cold chain.

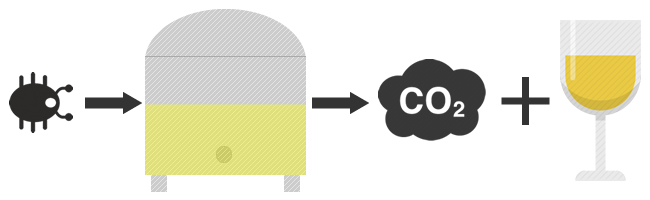

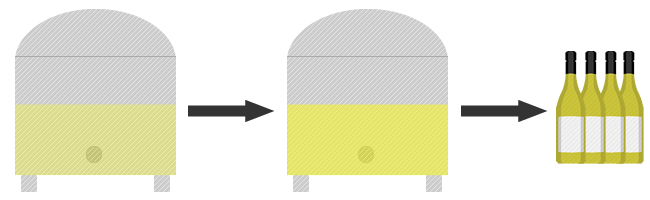

Fermentation

Fermentation is a critical process where the sugar in the must is converted into alcohol and gas by yeast. For white wines, fermentation typically occurs in large stainless steel tanks, although wooden barrels can also be used. Human intervention in this process includes selecting specific strains of yeast, controlling the fermentation duration, temperature (18°C - 20°C), final sugar content, chaptalization (adding sugar), and acidulation.

For semi-dry or sweet white wines, the fermentation process is halted at the desired sugar level using various chemical, manual, or physical methods, such as cooling the liquid.

Racking

After maceration, the wine undergoes racking, transferring it from one container to another to remove solid residues. This is usually done a couple of times between November and January, leveraging the protective low temperatures against microorganisms.

Clarification and Stabilization

Finally, proteins like egg whites are used to drag down any remaining suspended substances, concluding the process and allowing for the bottling of the wine. This step ensures that the wine reaches the consumer in its most refined and stable form.

In conclusion, the production of white wine is a blend of art and science, requiring precise techniques and careful handling at each stage. The result is a range of delightful wines that cater to diverse palates and occasions.

Founded in 2007, Vinetur® is a registered trademark of VGSC S.L. with a long history in the wine industry.

VGSC, S.L. with VAT number B70255591 is a spanish company legally registered in the Commercial Register of the city of Santiago de Compostela, with registration number: Bulletin 181, Reference 356049 in Volume 13, Page 107, Section 6, Sheet 45028, Entry 2.

Email: [email protected]

Headquarters and offices located in Vilagarcia de Arousa, Spain.